A fluorine-lined butterfly valve is a type of valve that is designed to handle highly corrosive fluids. The valve body and disc are lined with a fluoropolymer material, such as PTFE (polytetrafluoroethylene), PFA (perfluoroalkoxy), or FEP (fluorinated ethylene propylene), which are highly resistant to a wide range of chemicals. This makes them ideal for use in applications such as the chemical processing, pharmaceutical, and semiconductor industries.

Valve Body: The valve body is typically made of cast iron, cast steel, or stainless steel. The fluoropolymer liner is applied to the inside of the body using a variety of methods, such as sintering, extrusion, or spray coating.

Disc: The disc is also made of a metal material and is lined with the same fluoropolymer material as the body. The disc rotates on a shaft that is connected to an actuator.

Sealing: The valve seat is typically made of the same fluoropolymer material as the liner. The disc and seat form a tight seal when the valve is closed, preventing leakage.

Actuator: The actuator can be manual, pneumatic, hydraulic, or electric. It opens and closes the valve by rotating the disc.

Excellent corrosion resistance: Fluoropolymers are some of the most corrosion-resistant materials available. They can withstand exposure to a wide range of chemicals, including acids, bases, and solvents.

Leak-proof sealing: The tight seal between the disc and seat prevents leakage, even at high pressures and temperatures.

Lightweight and compact: Butterfly valves are lighter and more compact than other types of valves, such as globe valves and ball valves. This makes them easier to install and maintain.

Low maintenance: Fluoropolymer liners are self-lubricating and require minimal maintenance.

Bi-directional flow: Butterfly valves can handle flow in either direction.

Cost-effective: Fluorine-lined butterfly valve is often more cost-effective than other types of valves for corrosive applications.

Limited pressure and temperature ratings: Fluoropolymer liners can soften or melt at high temperatures. They are also not as strong as metal valves and may not be suitable for high-pressure applications.

Not suitable for abrasive fluids: Fluoropolymer liners can be abraded by slurries or other abrasive fluids.

Limited size range: Butterfly valves are typically available in smaller sizes than other types of valves.

Fluorine-lined butterfly valve is used in a wide range of applications, including:

Chemical processing: For handling corrosive chemicals such as acids, bases, and solvents.

Pharmaceutical: For handling pharmaceutical products and intermediates.

Semiconductor: For handling ultrapure water and other critical fluids.

Pulp and paper: For handling bleaching chemicals and other corrosive fluids.

Food and beverage: For handling food and beverage products.

Water treatment: For handling chlorinated water and other corrosive fluids.

When selecting a fluorine-lined butterfly valve, it is important to consider the following factors:

The type of fluid being handled: Make sure the valve is compatible with the specific chemicals that it will be exposed to.

The pressure and temperature: Choose a valve with pressure and temperature ratings that are higher than the maximum conditions that it will see in service.

The flow rate: Select a valve that is sized correctly for the desired flow rate.

The actuator type: Choose an actuator that is compatible with your control system and has the required torque output.

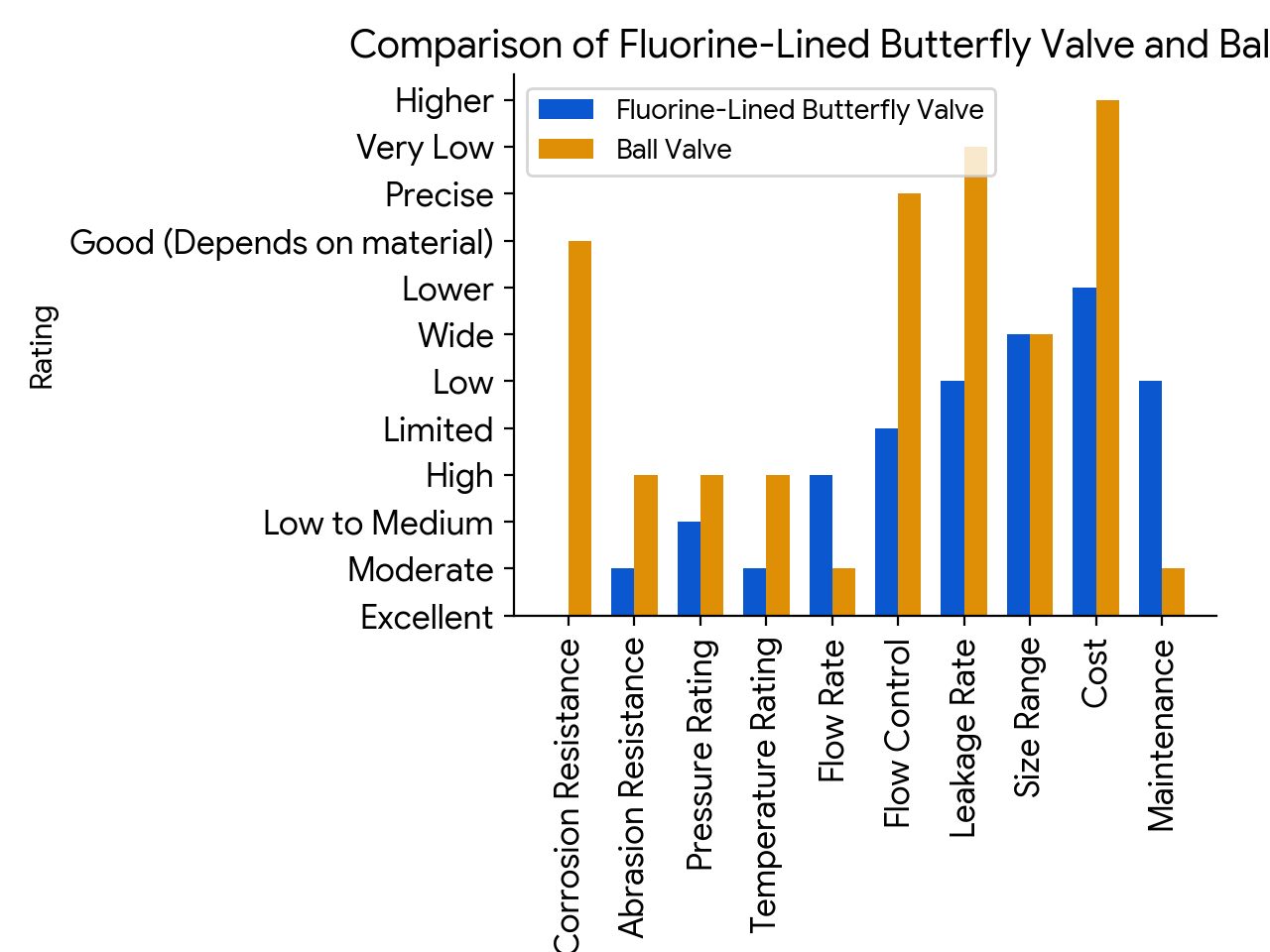

| Feature | Fluorine-Lined Butterfly Valve | Ball Valve |

|---|---|---|

| Disc/Ball Material | Metal lined with fluoropolymer (PTFE, PFA, FEP) | Metal (stainless steel, bronze, etc.) |

| Sealing Mechanism | Disc and seat contact | Ball and seat contact |

| Corrosion Resistance | Excellent (fluoropolymer liner is highly resistant to most chemicals) | Good (metal body may corrode depending on specific material and fluid) |

| Abrasion Resistance | Limited (fluoropolymer can be abraded by slurries) | Good (metal is more resistant to abrasion) |

| Pressure Rating | Lower (typically up to 300 psi) | Higher (typically up to 1500 psi) |

| Temperature Rating | Lower (typically up to 200°C) | Higher (typically up to 400°C) |

| Leakage Rate | Very low (can be zero-leakage with proper design) | Low (tight shut-off, but small leaks possible) |

| Flow Rate Capability | High (bi-directional flow) | Moderate (uni-directional flow) |

| Size Range | Wide range (typically up to 48 inches) | Wide range (typically up to 48 inches) |

| Cost | More cost-effective for corrosive applications | More expensive than butterfly valves |

| Maintenance | Low (fluoropolymer is self-lubricating) | Moderate (periodic lubrication and seal replacement) |

| Applications | Chemical processing, pharmaceutical, semiconductor, pulp & paper, food & beverage, water treatment | General purpose, oil & gas, power generation, mining |

Fluorine-lined butterfly valves are a versatile and cost-effective solution for handling corrosive fluids. They offer excellent corrosion resistance, leak-proof sealing, and low maintenance. However, it is important to carefully consider the application requirements and select a valve that is properly sized and rated for the intended use.